DEER Platform Integrated, Intelligent, Incomparable.

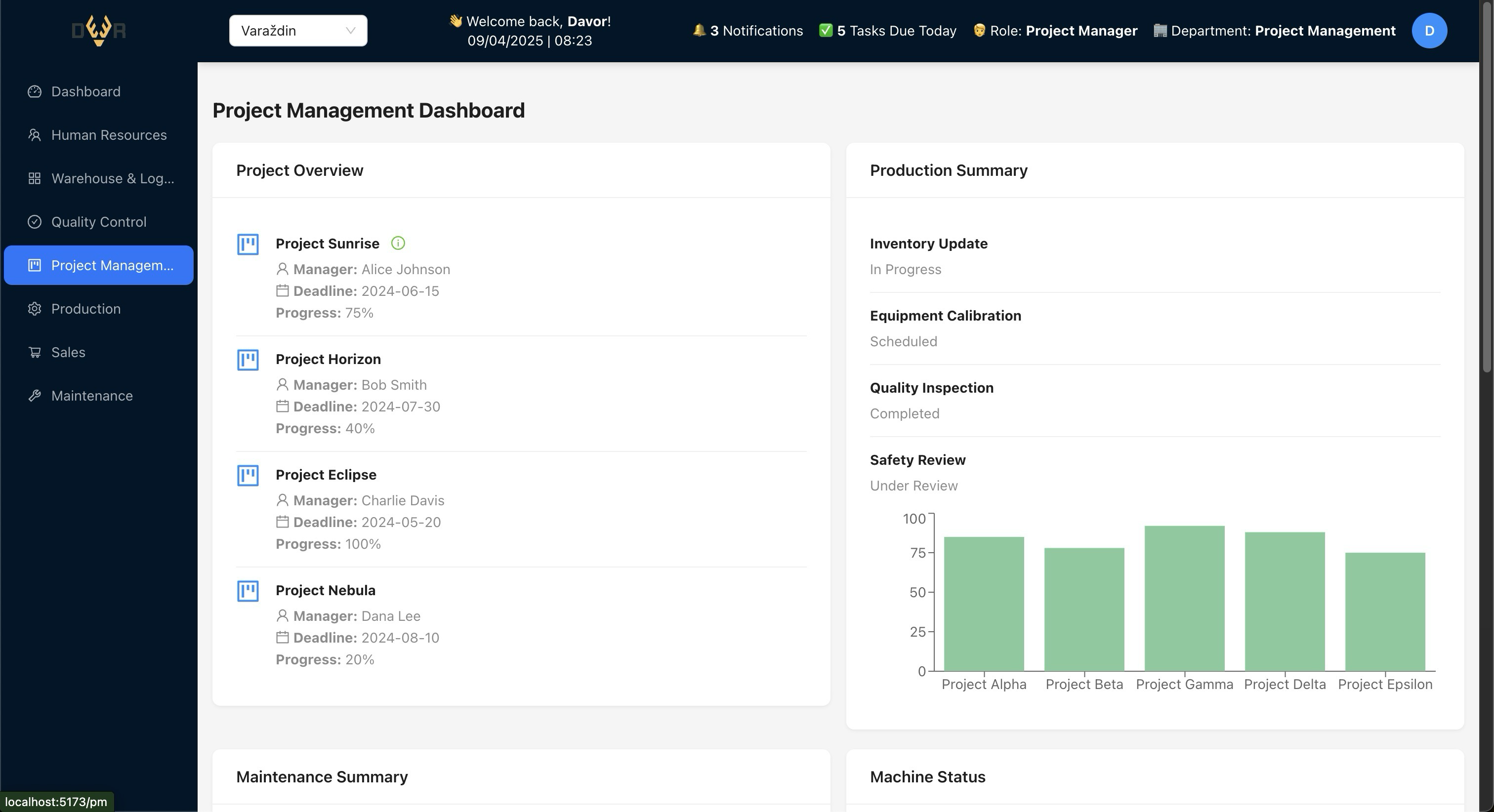

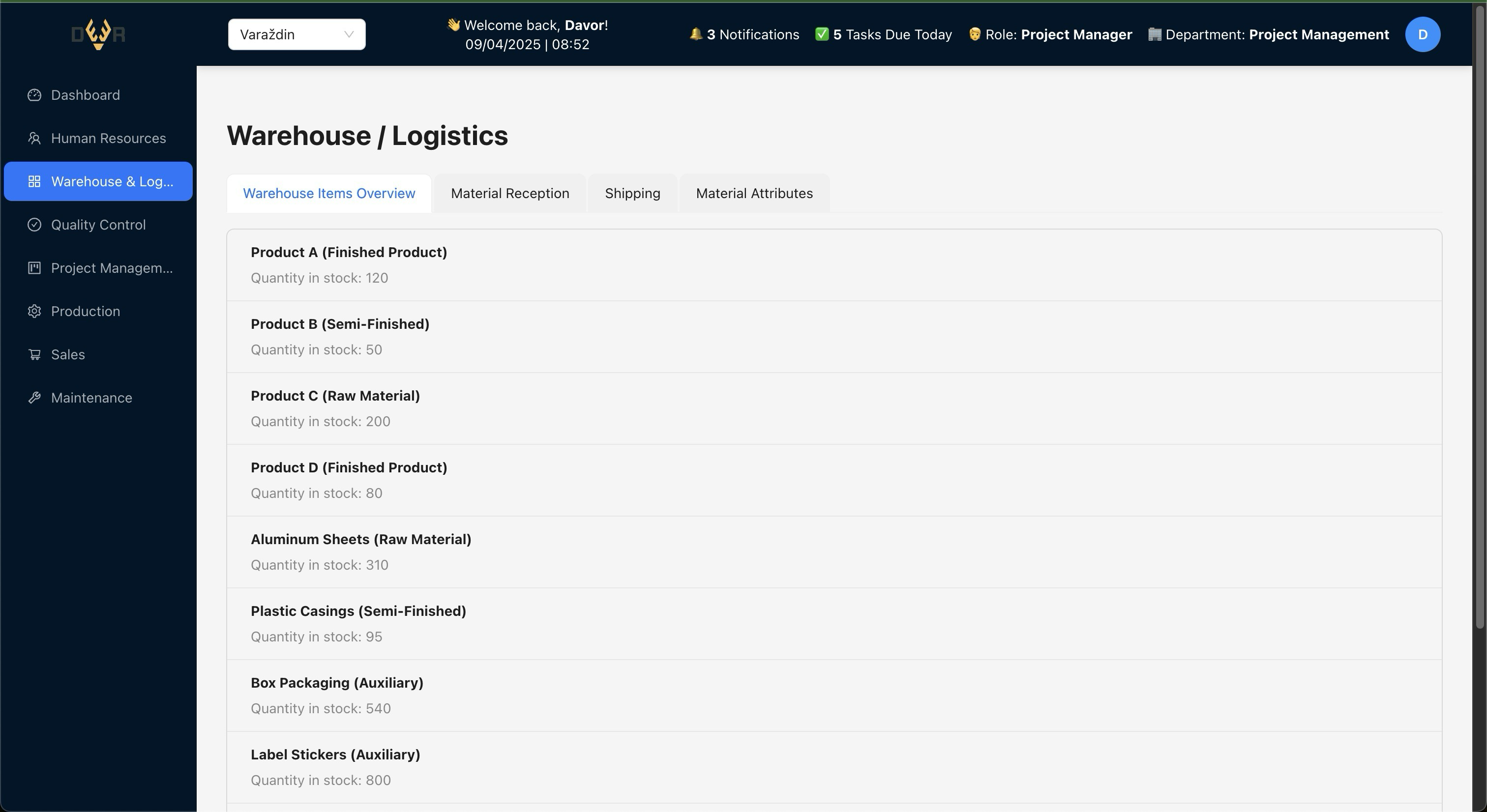

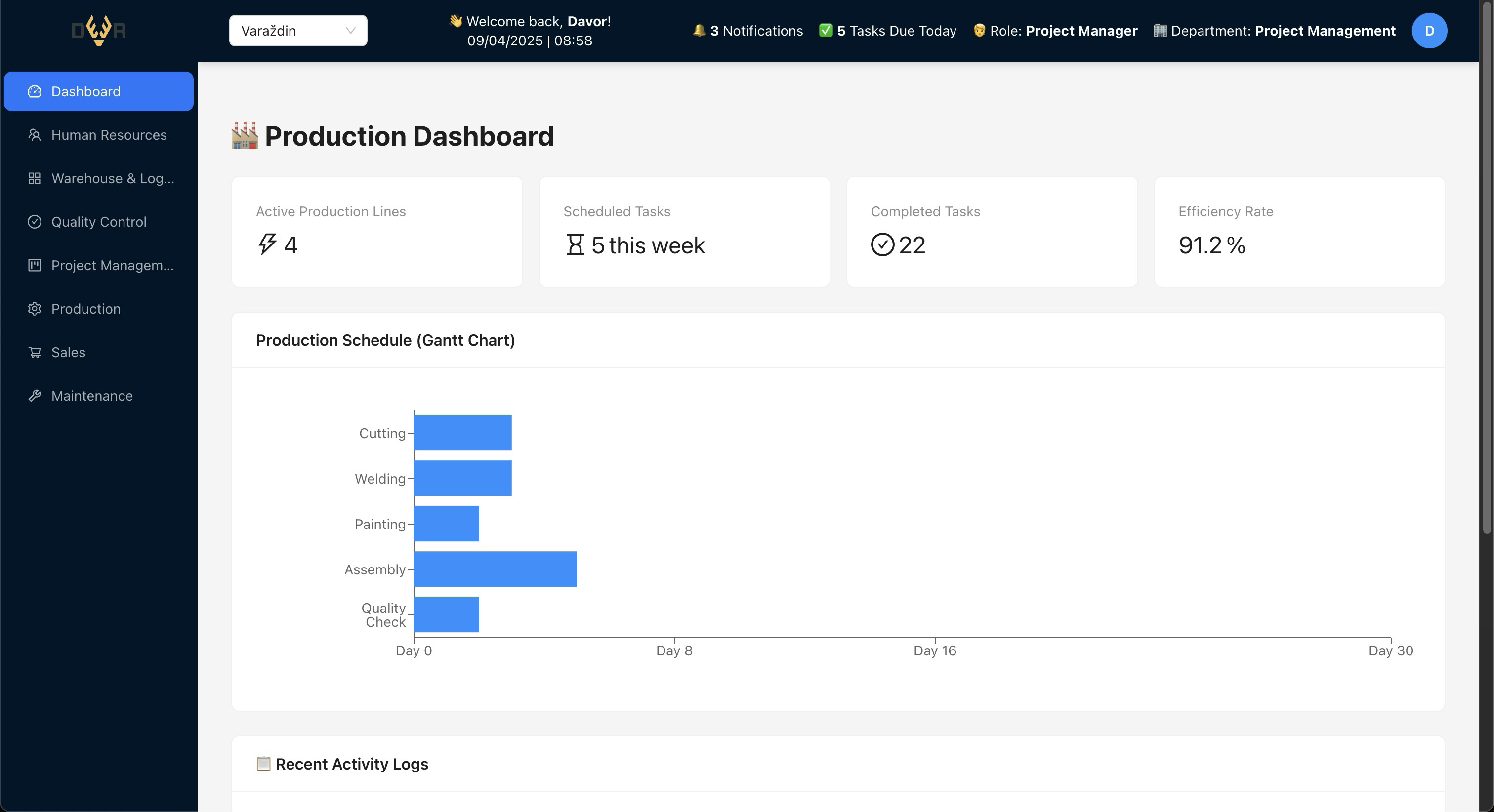

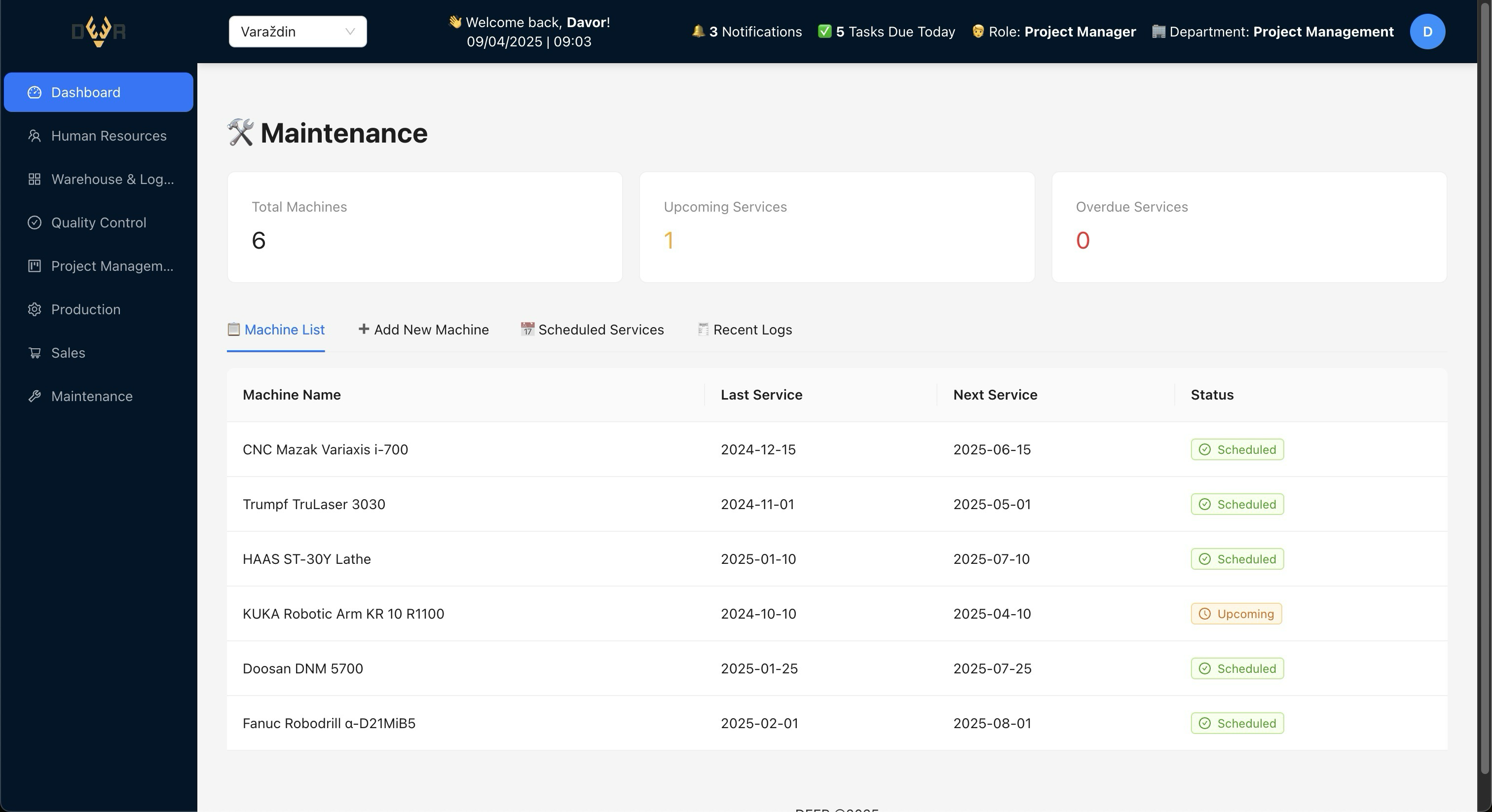

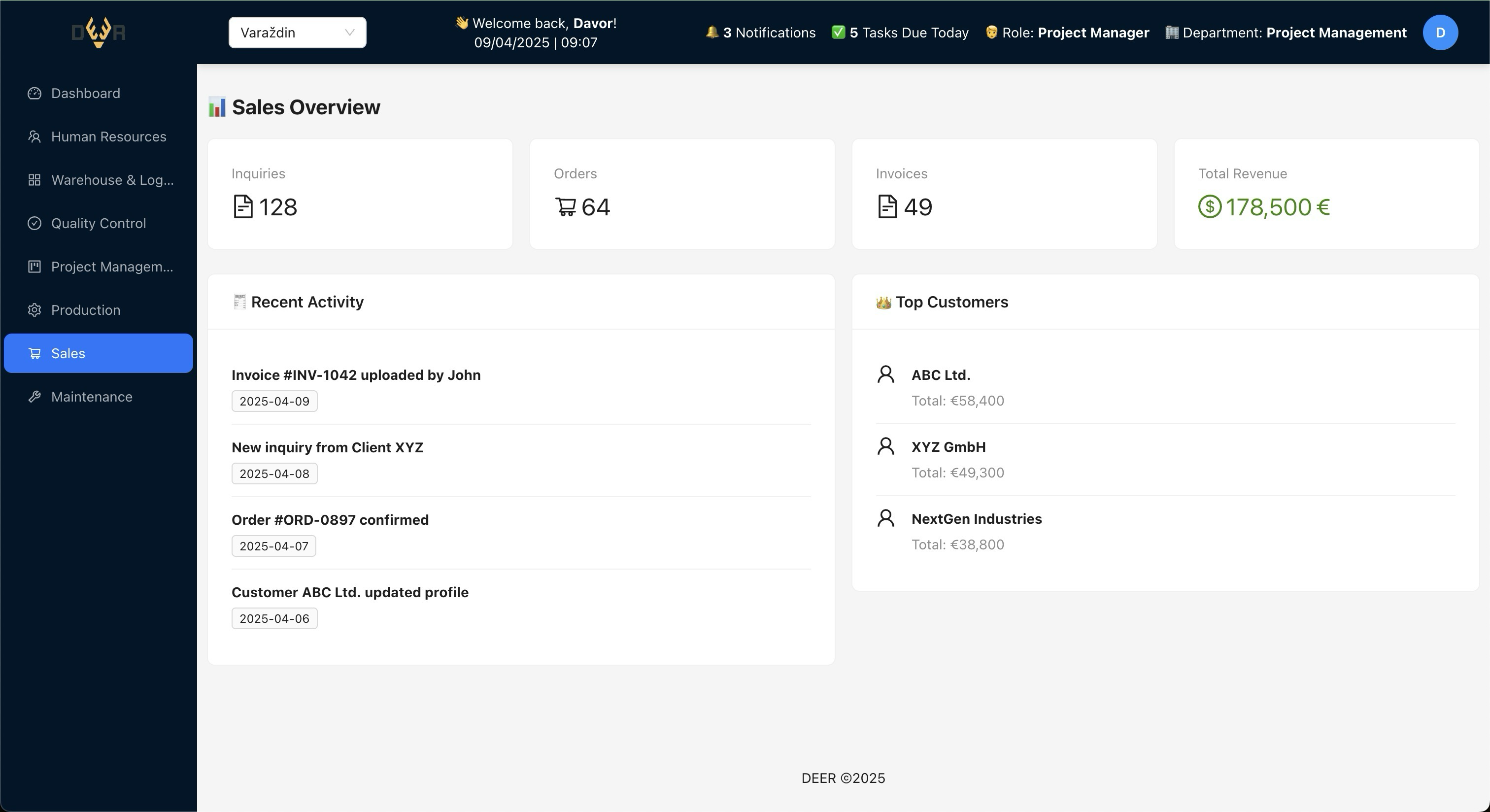

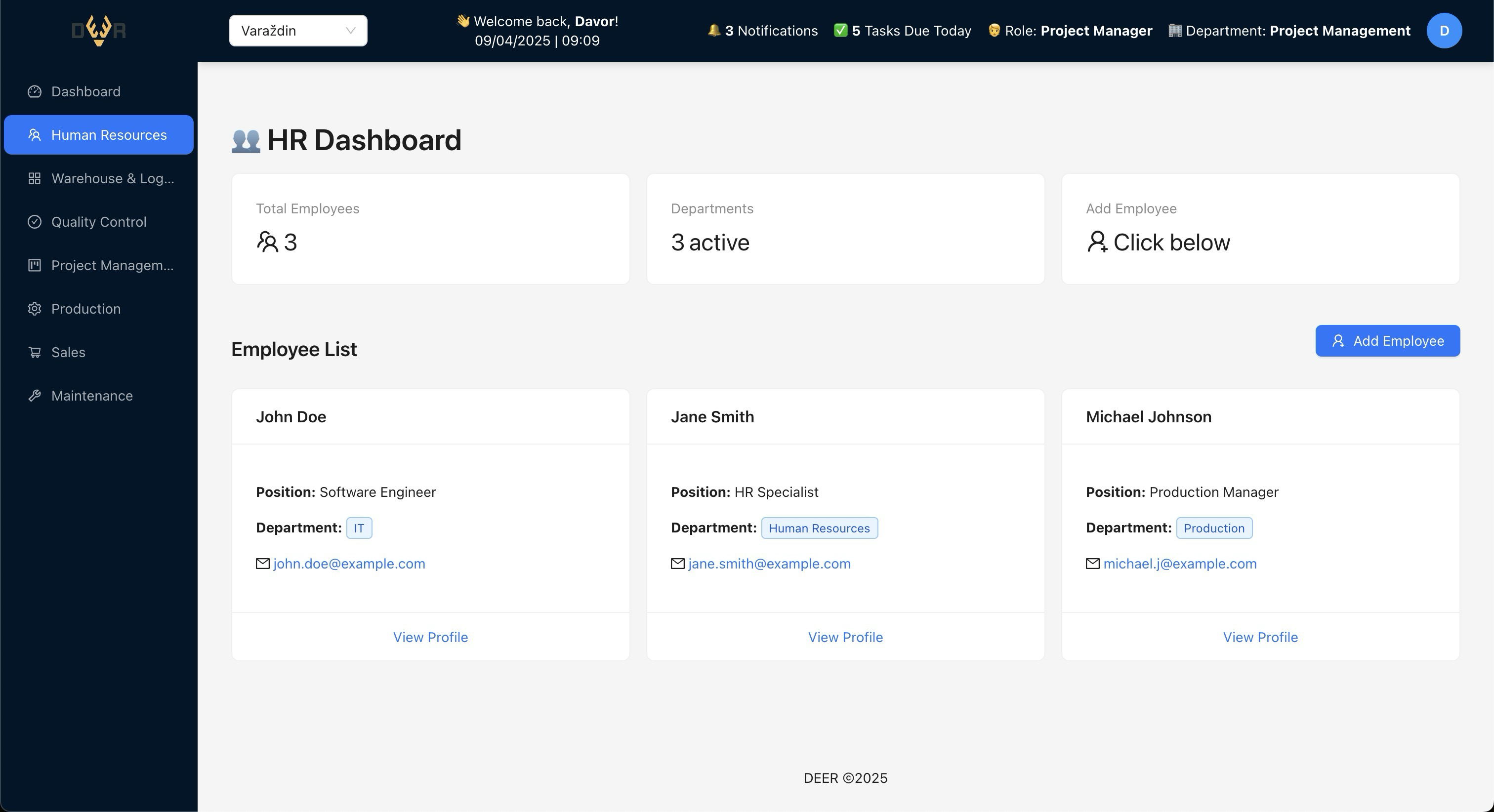

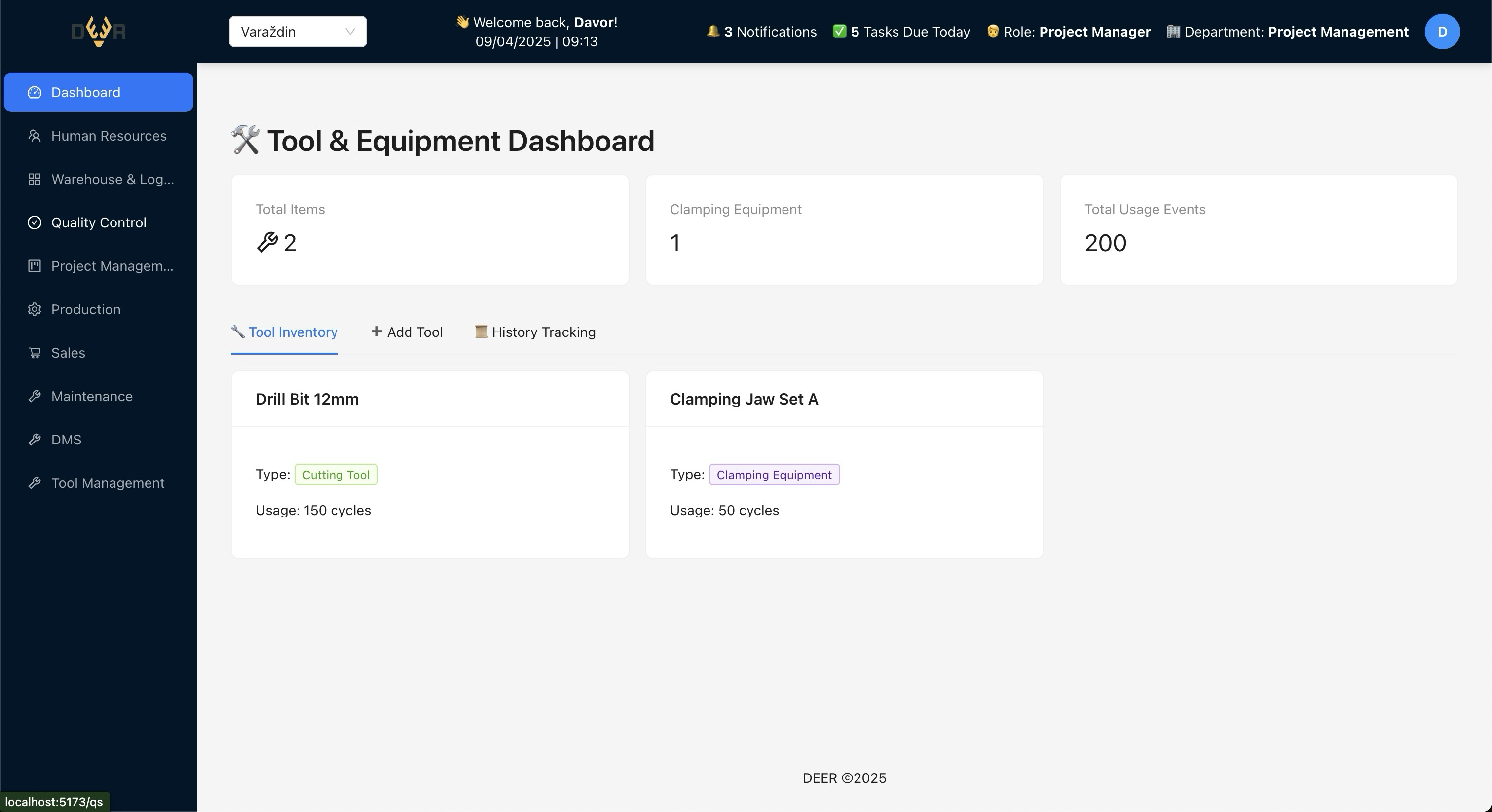

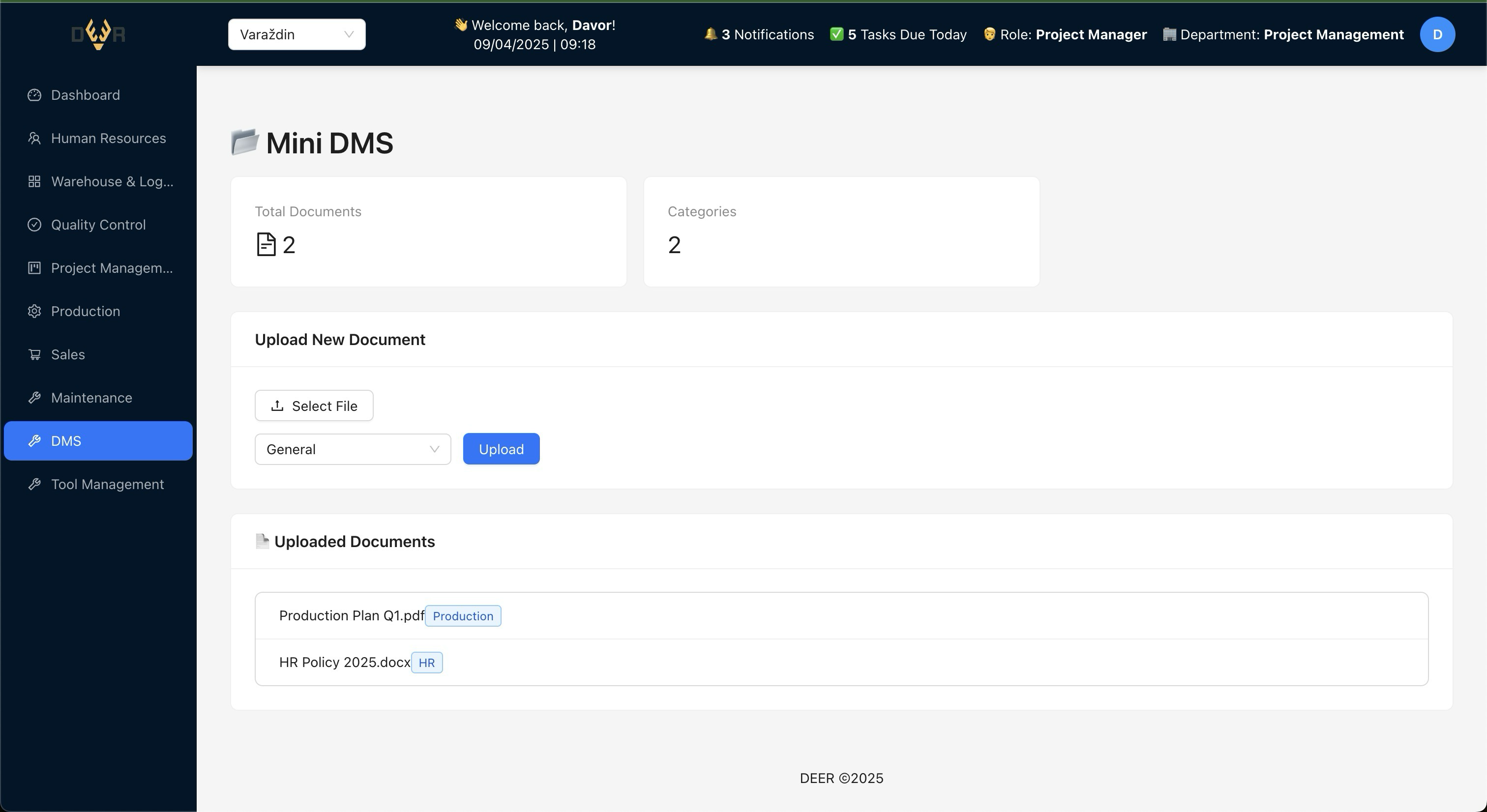

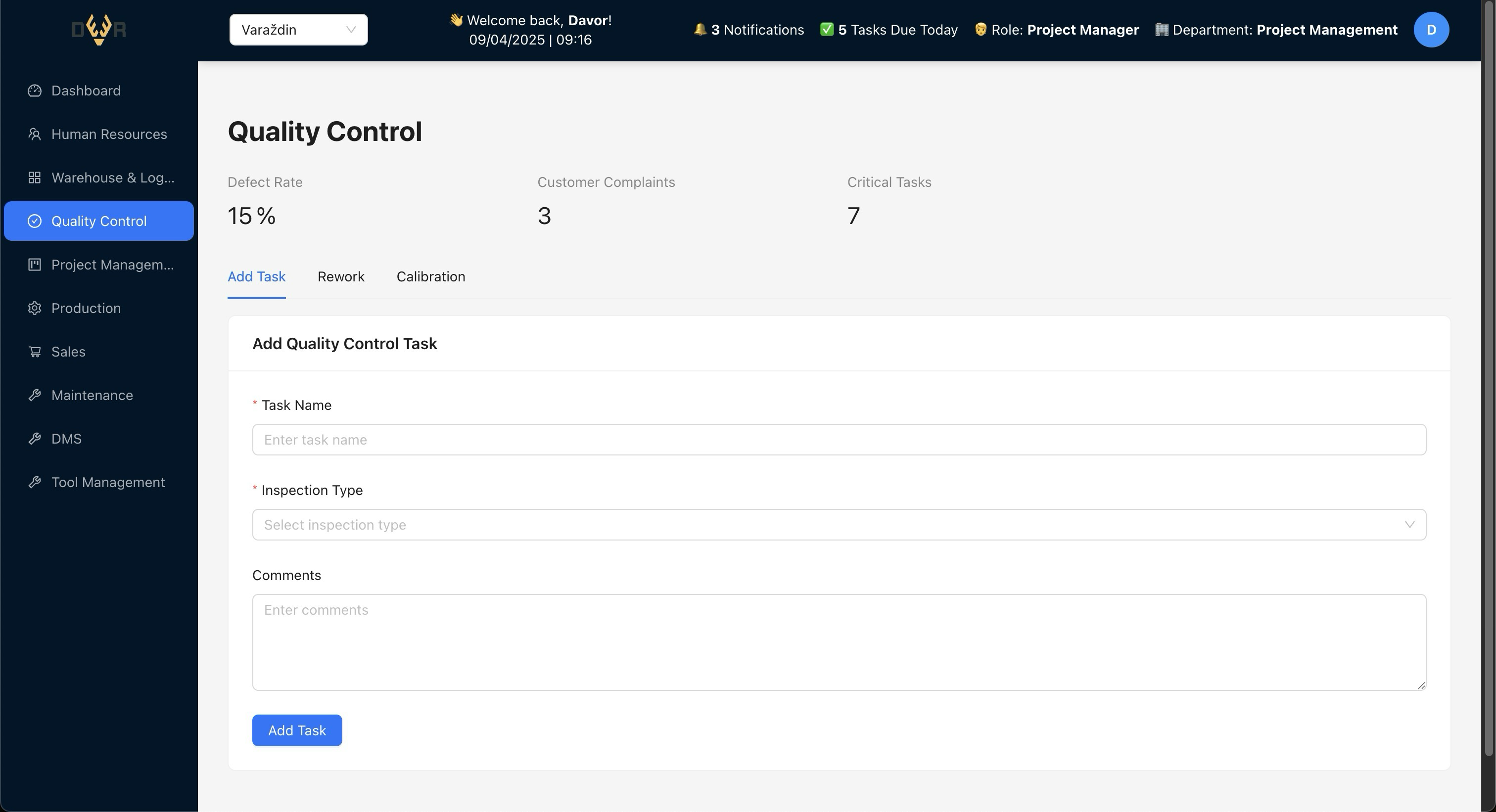

This application is designed to streamline operations in CNC machining and similar industries by providing a comprehensive suite of tools for task management, project tracking, resource and people allocation, and reporting. It supports 9 modules for production and project planning, calculation, maintenance, sales and purchasing, HR, QS, and more, offering an integrated solution for managing workflows and optimizing efficiency. Users can track tasks, manage inventories, schedule maintenance, and generate detailed reports, all through an intuitive dashboard. With customizable layouts and visual management tools, the application adapts to the specific needs of each organization, enhancing productivity and collaboration across departments.